The first phase of PiQ development began in a meeting among shop floor employees. The question was posed: What is the biggest problem on the shop floor?

The first phase of PiQ development began in a meeting among shop floor employees. The question was posed: What is the biggest problem on the shop floor?

The overwhelming answer was “communication.” I needed them to be more specific, because communication is a broad topic. The team started firing off examples.

- I came in for my shift, and I asked what is most important to run. Joe tells me to focus on Machine #10. I spend my evening optimizing production on Machine #10, and then the next day Bob tells me that I was supposed to be focused on Machine #8.

- I ran Machine #22 for my entire shift, then the next day I was admonished for overproducing the order by 20%. No one told me how many more parts we needed.

- We missed our shipping date on Part A because no one told me that it was due to ship tomorrow, and I was focused on Part B.

- We ran out of material for Machine #13 yesterday. I told Bob that we needed more material, and he didn’t get the message to Jill.

The company managed orders on a white board in the Operations Manager’s office. Each day, the Operations Manager revised the board with due dates and quantities. He knew everything that needed to be done, and when it needed to be completed. No one could fault his organization nor his knowledge. However, the problem arose in the communication of requirements to the rest of the shop floor. The grapevine effect was taking its toll.

We’ve all heard of the grapevine. Most of us think of it as an informal communication network, a “gossip channel.” But in Production Management, the grapevine has more significance. To illustrate this phenomena, we did an exercise in a team meeting. All of the employees were sitting at a large, U-shaped table. I went to one end of the table and whispered in the first employee’s ear: “We’re going fishing on Tuesday, pass it on.”

The information went around the table, from one person to the next. I went to the other end of the line and heard from the last person “The shop will be closed on Wednesday!”

The lesson is that verbal communication becomes distorted in a team environment, because each person hears the information within their own perspective, and communicates it to others from their perspective.

What this team needed was a Production Management System: Software that centralized the information and made it accessible to everyone. With a background in ERP systems in Fortune 500 companies, I knew where to start. I began researching small shop production software.

In short, here is what I found: My minimum investment was going to be in the $20K – $30K range. Yes, there were packages that advertised for less than half of those figures, but as an experienced systems implementer, I knew that consultation and customization to make the software fit our environment would be at least the cost of the software itself. So I developed the application internally.

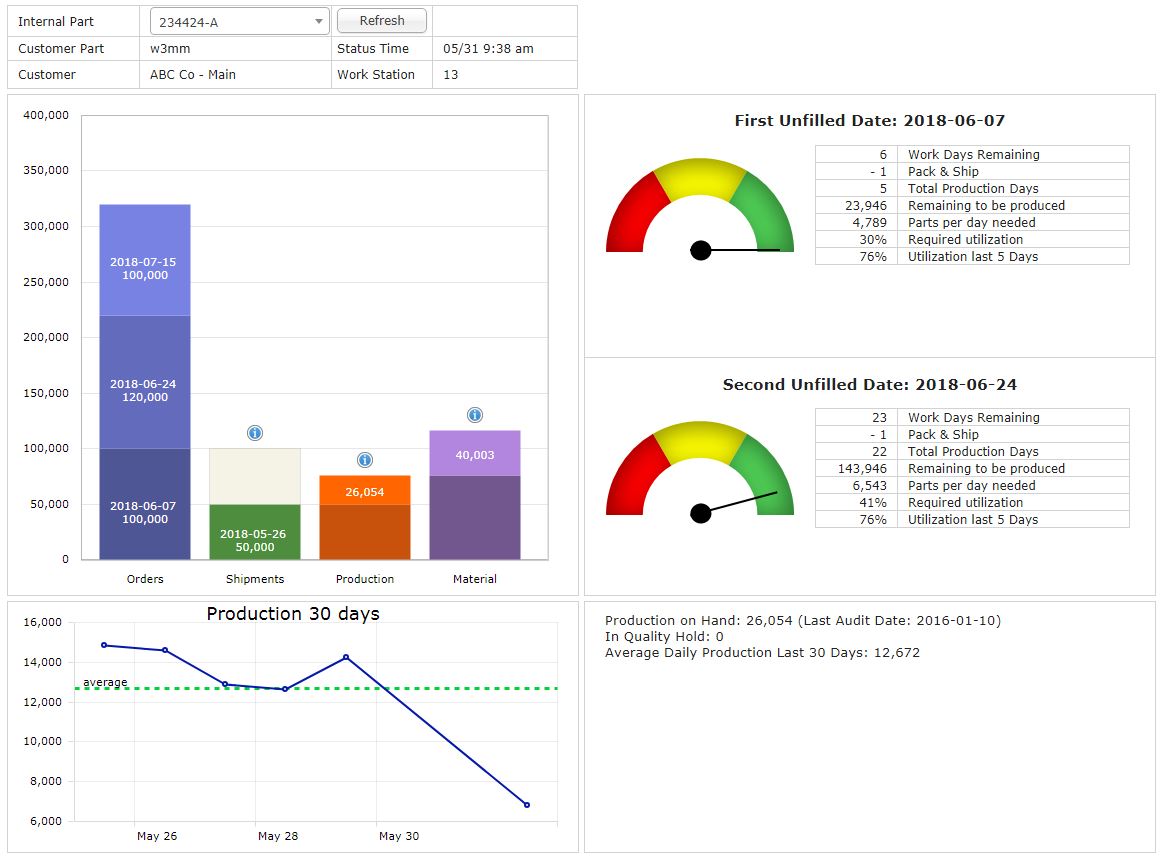

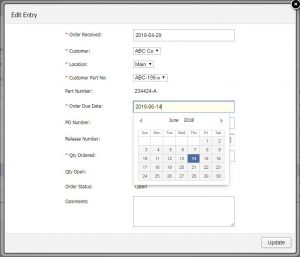

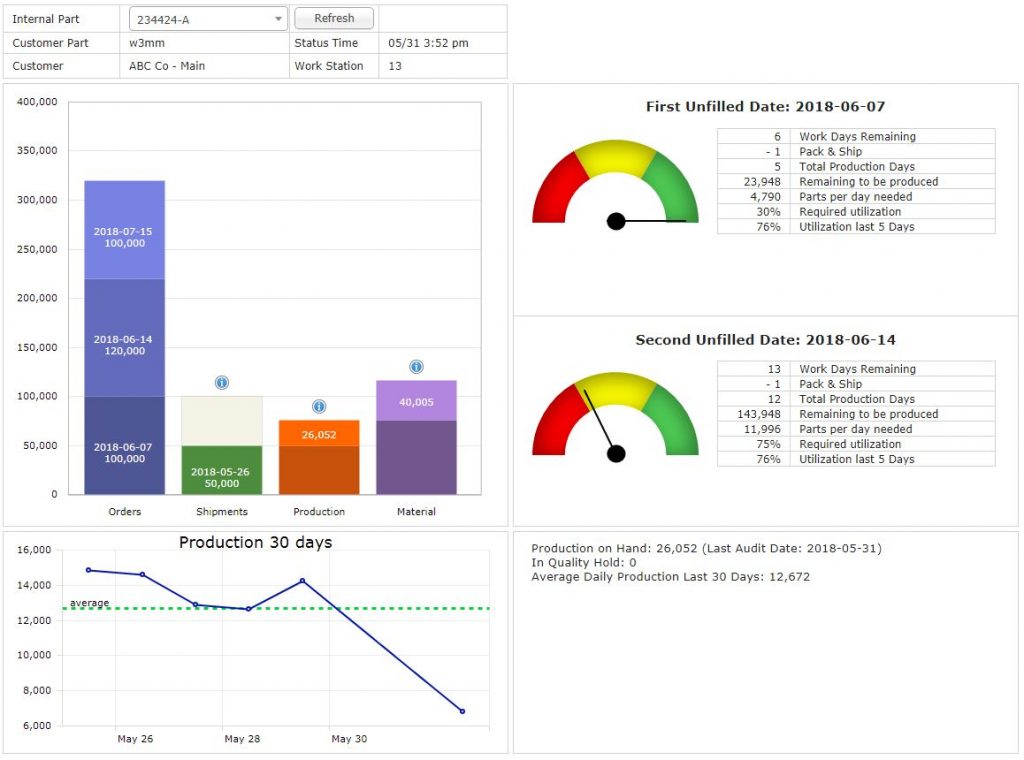

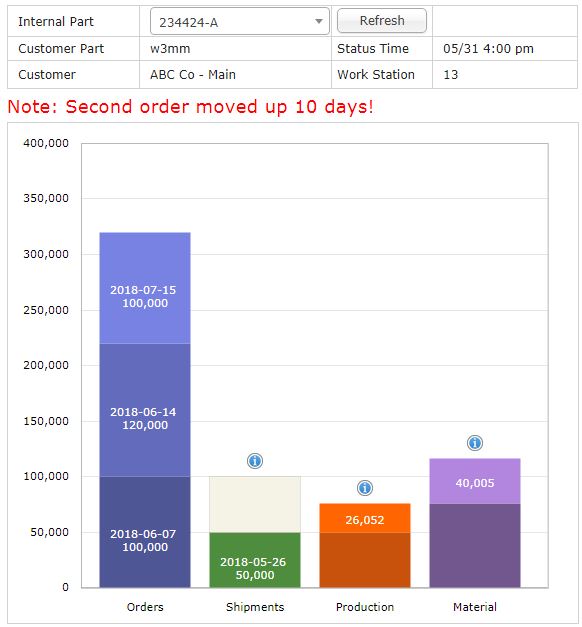

The first requirement was to assure that the information was presented graphically, so the shop floor employees could understand it easily. Implementation and training were simple, and the application was quickly embraced. Within days, the “communication problem” never came up again. Here is what I observed:

- No one complained that they didn’t know how to prioritize their work again.

- Shop floor employees were proactively passing valuable information to management. Some examples:

- We’re running low on material for Job A.

- It’s going to be close to make the order for Job B on the 16th. I am available to work on Saturday, would you like me to come in?

- I can finish Job A on Machine 10 tonight, and if we change it over to Job B, we won’t be in a pinch for the next order.

- Shop floor employees were helping each other. When one operator knew that his colleague’s job was in a pinch, he helped with the loading process of the constraint machine, cutting loading time in half.

- Production runs stopped when they were complete. Everyone understood how many parts we had, and how many we needed.

By giving everyone on the shop floor access to all of the information they needed to do their job, we eliminated communication issues and streamlined our operations.

Today, that package is available to your company, with zero start-up cost and a small monthly fee. Check out the demo and see how PiQ can improve your operations!